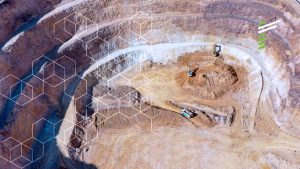

To reduce operational costs and comply with shifts in Indonesian processing and environmental regulations, diesel and tire usage should be optimised for greater savings and reduced emissions.

Vast amounts of data can be generated by today’s mining equipment through sensors, AI, and machine learning. However, the time and resources to clean that data is an impediment, if not a barrier, for many companies.

Beyond cleaning and capturing data, the ability to analyse and share the information on-shift is the edge that sets mining companies apart from competitors. Our specialist mining practice uses proprietary analytics to identify improvements in the routes, cycle times, loaded and unloading gearing, and operator skills.

Many patterns in data, such as the duration between a distressed tire and its failure, or diesel and tire usage assessed in efficiency by unit, represent an advanced use of data.

Ready for a change in your organisation?

However, we find many clients attempting to implement advanced data analytics, while the ability to collect, interpret and use basic data is not fully in place yet. Without the behavior changes, processes and systems to support the use of these advanced systems, full adoption will prove to be elusive.

In addition, we find that data is not presented in a manner that most employees can understand or apply to their routines. Hence, by developing systems that present the relevant information to employees at the right time to enhance their specific tasks, data can more effectively be leveraged to reward or incentivise employees to meet clearly defined targets.

Whether you’re ready to apply advanced analytics or ensuring your basic data is clean and useful,

Renoir Consulting can work with you at your sites, at your headquarters, in person and remotely.

Leverage your data to optimise diesel usage for greater savings