At a Glance

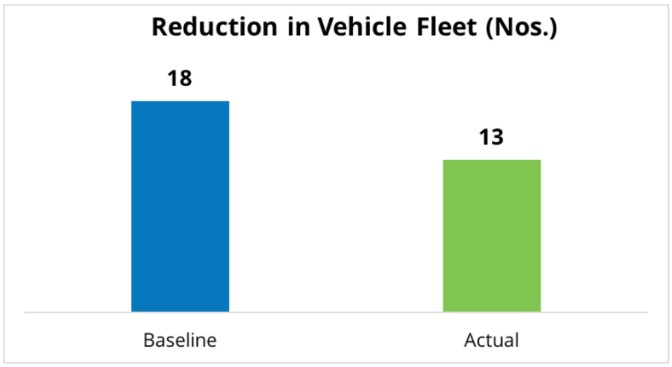

- With improved performance monitoring systems, the client was able to reduce its vehicle fleet size by 27% for operational cost savings

- Systematic fraud verification systems were also installed to deal with defaulters and reduce commercial losses

- A robust Management Control System and training was implemented to support continuous improvement beyond the project’s closeout

Background

The client is one of the biggest private utilities companies in South America in the sanitation sector, serving more than 5 million people. The company develops tailor-made sanitation solutions for municipalities across various cities and states.

The Challenge

Renoir Consulting was hired to support the management team to identify and implement process improvements across its Operational, Commercial and Electromechanical areas. The goal was to increase the productivity of field teams, raise service levels, reduce operating costs and increase revenue sources.

Analysis

An initial question the Renoir team explored was regarding the client’s Management Control System (MCS). How effective was it in enhancing the productivity of teams?

The next step was to determine preventive actions to assess and improve operational performance, as well as understanding how well the MCS identified deviations to required performance and costs. The following were shortlisted as the biggest opportunities for the client:

Productivity of the Commercial, Maintenance and Operations teams

Vehicle fleet management, programming and utilization

Route optimization solutions for meter reading

Managing defaulting clients

Manager alignment with company guidelines and response training for underperforming workers

Improving the capability of KPIs to provide clear performance understanding to employees

Project Approach

The goal was to develop and implement sustainable changes to the client’s management control system that would support cost reductions, management practice improvements, making performance information readily available and developing KPIs that support decision making in a structured manner. Two work streams were identified and worked in parallel:- Operational, with a focus on productivity management processes

- Commercial, focused on the programming of services and defaulter collection.

- A revision of routines for work teams and field officers for optimal performance

- Optimization of vehicle utilization and comprehensive preventive maintenance plans

- Correct work assignments and registering of work done

- Ongoing analysis of workforce behaviour, skills and establishing guidelines to monitor productivity

- Short interval control training of operatives and leaders and assignment of work to teams in shifts

- Implementation of root cause analysis techniques to proactively manage variances in performance

Key Results

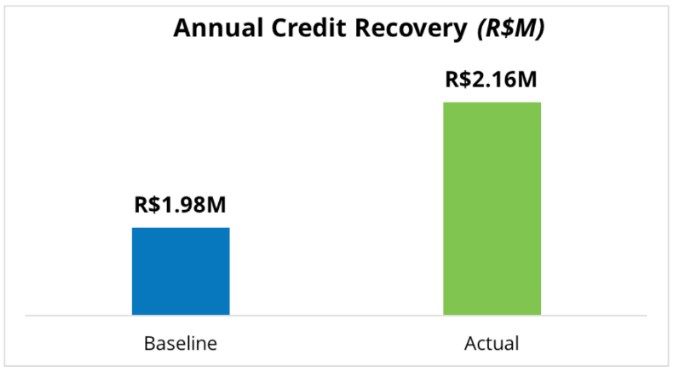

After 27 weeks, the results achieved surpassed Renoir’s baseline targets:“I now have the opportunity to pursue improved productivity based on structured information.”

– Maintenance Services Department Coordinator

Implementation

After 27 weeks of the client and the Renoir team working closely together, an updated management control system was implemented involving the client’s Operational and Support areas, complemented with training at all levels to ensure sustainability of the system. As a result, the client achieved:

Enhanced Utilization of Resources

A field team structure was created that now ensures the best distribution and utilization of labour and the reduction of third parties. By rightsizing its vehicle fleet through enhanced performance management, the client was also able to achieve significant cost savings. Commercial agents could also maximize their available time after reviewing meter reading routes for optimization.

Cost Savings and Loss Prevention

To reduce commercial losses, commercial agents were trained in carrying out critical analysis to identify consumption deviations. Meanwhile, better procedures for dealing with defaulting clients such as systematic fraud verification procedures were enacted.

Continuous Improvement

An internal taskforce within the client’s company was trained to identify and quantify future opportunities using Renoir’s methodology, ensuring long-term improvements. A methodology for situational auditing, conducting meetings and reporting was also practised to improve conformity to the new management control system implemented.

Gain a bird's eye view of your company performance with a robust Management Control System.