At a Glance

- European global oil and gas company partnered with Renoir to address rising maintenance backlog and inefficiencies in its Work Management (WM) processes, which posed risks to operational reliability and the transition to SAP S/4HANA.

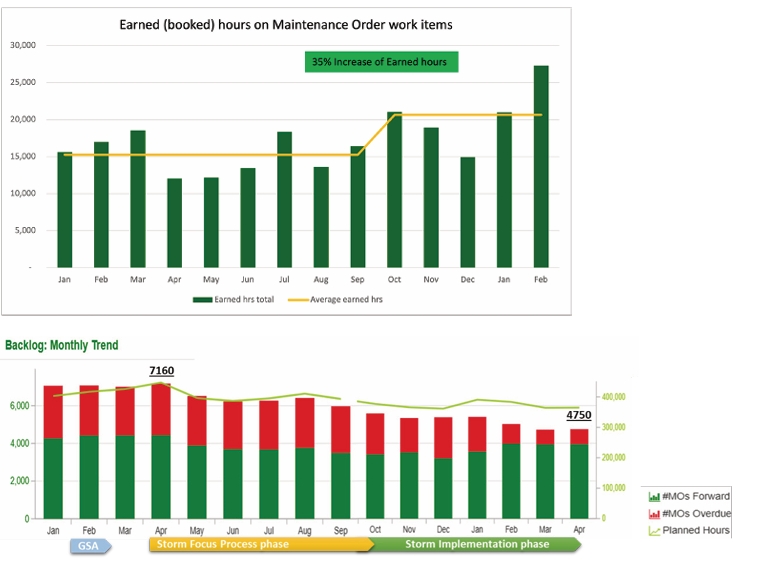

- With a collaborative and structured transformation, the client achieved a 35% increase in executed hours in the field.

- This case study explores how structured work management improvements and embedded KPIs led to a 35% increase in field execution.

Key results

35% increase in hours executed in the field

Over 2,100 maintenance orders cleared from backlog (a 30% reduction)

Maintenance order overdue percentage reduced from 37% to 19%

Supervisory time in the field increased from 33% to 43%

Background

The client is one of the world’s leading oil and gas companies, operating across the entire value chain, including upstream, refining, distribution, and marketing. This case focuses on a major refinery in Europe, with a production capacity of approximately 400,000 barrels per day.

Refining remains a capital-intensive sector that demands high asset uptime, strict safety standards, and consistent operational efficiency. Globally and across Europe, investment in refinery infrastructure is declining. According to the International Energy Agency (IEA), refinery investments are expected to drop to around $30 billion in 2025, the lowest in a decade. No net capacity additions are forecasted due to refinery retirements and reduced capital deployment. This reinforces the need for efficient maintenance strategies and digital transformation to extend the life and performance of existing assets.

Analysis

The client was facing a growing annual maintenance backlog, with a significant portion comprising overdue work orders. This backlog was beginning to impact operational control and posed a risk to overall site reliability. Compounding the issue was the inconsistent application of established Refining Work Management (WM) best practices, which the client recognised would present challenges in their upcoming transition to SAP S/4HANA.

Renoir conducted a comprehensive diagnostic of the client’s WM practices, which included shop floor observations, stakeholder interviews, targeted workshops, and detailed data analysis.

Several critical issues were identified:

- Technician wrench time was measured at only 29%, largely due to upstream inefficiencies such as poor scheduling and low-quality work preparation.

- Although local procedures were aligned with standard WM frameworks, execution on the ground was inconsistent. This was partly due to insufficient training and understanding among personnel.

- There were underlying organisational challenges, including gaps in performance management, ineffective meetings, and behavioural inconsistencies. Key performance indicators (KPIs) were either absent or not effectively integrated into meetings, limiting visibility and alignment across functions.

In response, a project was launched with two core objectives:

- To improve executional productivity and reduce the maintenance backlog, thereby mitigating site-level operational risks.

- To implement and embed standardised Refining WM practices that would support the client’s transition to SAP S/4HANA.

Optimise Subcontractor Management and Progress Tracking

Reduce Operating Costs with Optimized Performance Management

Ready for a change in your organisation?

Project Approach

Renoir structured the project into Management Action Teams (MATs). The engagement followed Renoir’s Focus Phase® methodology to identify root causes and co-develop solutions with the client.

Key actions included:

- Conducting workshops, data analysis, and shopfloor observations

- Deploying scrum sprint methodology for weekly progress across MATs

- Training stakeholders in new procedures and change management

- Regular governance meetings with site and global leadership teams, on a fortnightly basis.

“Due to the MCS leading and lagging indicators, we are now able to monitor the work management processes and now can steer upon data. Renoir was able to provide us with a professional and multiple disciplined team, bringing a good mix between theoretical and practical experience.”

-Maintenance and Engineering Manager

Implementation

During implementation, the team uncovered various design flaws and process gaps, which were addressed through clearly defined actions presented during the Strategic Integration Meeting. Stakeholders received structured training and coaching on updated procedures to align with the desired future state.

Key initiatives implemented during the project include:

- Trained all notification creators in best practice standards

- Improved risk ranking validation processes using updated global standards

- Enhanced planning procedures, work instructions, and created a planning handbook

- Delivered standardised training for new and existing employees

- Adjusted SAP system parameters for material availability and accurate supplier lead times

- Established stage gates with strict readiness criteria for scheduling

- Corrected planning errors before final schedule freeze and addressed non-readiness proactively

- Mapped roles and responsibilities with a structured feedback loop for continuous improvement

- Redesigned meeting structures and implemented updated Terms of Reference

- Embedded KPIs into dashboards to monitor process performance and drive accountability

- A shift from top-down communication to bottom-up performance meetings enabled timely issue resolution and strengthened the Plan-Do-Check-Act (PDCA) cycle.

- Provided coaching for first and second-line shop floor leaders to improve field execution

Result

Six months into the implementation, the project delivered tangible and sustainable outcomes:

- Field execution improved significantly, with 35% more hours executed

- Over 2,100 maintenance orders were cleared, reducing backlog by 30%

- Overdue maintenance orders dropped from 37% to 19%

- Supervisors spent more time in the field, rising from 33% to 43%

- New processes, procedures, and training materials were fully embedded

- Performance ownership increased, and meeting maturity improved across the board

The top chart shows a 35% increase in earned (booked) maintenance hours over the project period, reflecting improved execution efficiency.

The bottom chart illustrates the steady reduction in backlog, with overdue maintenance orders declining significantly from the start of the implementation phase. The data spans the GSA, Focus Phase, and Implementation Phase.

The partnership fostered a performance-driven culture with real-time data monitoring, positioning the client for a smoother SAP S/4HANA transition and ongoing operational excellence.

*We have intentionally omitted client-specific details to maintain strict confidentiality.

Optimise your maintenance operations and reduce backlog risk.