At a Glance

- A prominent utility provider faced operational inefficiencies due to excessive manual work and lack of standardised procedures.

- Renoir was engaged to help automate processes, standardise material coding, and improve the project lifecycle.

- This case study discusses how process optimisation unlocked 180% improvement in budgeting compliance through automation.

Key results

Reduced manual workload by 12%–16%

Decreased material write-offs by 9%–13%

Achieved over 180% increase in budgeting compliance through standardised codes and automated checks

Improved execution of regulated steps by 19%–26%

Background

Brazil has one of the most extensive and complex electricity markets in Latin America. Recent data shows an installed capacity of over 190 GW, with more than 60% from hydroelectric power, followed by wind, solar, and thermal energy. The national power grid is vast and requires coordination, maintenance, and compliance. Utilities are accelerating digital transformation, grid automation, and process standardisation to improve performance.

The client is one of Brazil’s largest integrated electricity distributors. It supplies power to over 20 million people across 860+ municipalities and is a critical player in ensuring energy access and reliability.

The company has invested heavily in recent years in upgrading grid infrastructure and improving service quality. With 1,600 personnel based in one key area, it is central to the state’s energy supply and socioeconomic development.

The client collaborated with Renoir to optimise internal processes, reduce inefficiencies and align operational execution with regulatory, shareholder and customer expectations. The transformation focused particularly on enhancing performance in the design, construction, and maintenance of distribution projects — core functions essential to sustainable energy delivery.

Analysis

The client recognised critical opportunities to improve project delivery by addressing inefficiencies in the DCMD department. Processes were heavily manual, and valuable employee time was consumed by low-value administrative tasks.

Additional challenges included:

- Inconsistent processes and documentation

- Lack of automation across core project steps

- Disjointed controls between regulated and non-regulated activities

- Manual material tracking and financial compensation errors

The client sought to optimise the entire project lifecycle by streamlining operations, automating repetitive tasks, and strengthening information controls.

Reduce Operating Costs with Optimized Performance Management

Optimise Subcontractor Management and Progress Tracking

Reduce Operating Costs with Optimized Performance Management

Optimise Subcontractor Management and Progress Tracking

Ready for a change in your organisation?

Project Approach

Renoir collaborated with the client to develop a structured transformation plan, focusing on the following key areas:

- Evaluation of all critical processes across departments

- Identification of activities triggering financial inefficiencies

- Redesign of engineer and supervisor routines for clarity and control

- Definition of new control points and indicator measurement frequencies

- Mapping of all existing procedures and automation opportunities

Internal alignment sessions were held with the client’s leadership and third-party service providers to ensure buy-in and consistency.

“After structuring the management system and processes, the objective was to automate administrative processes to reduce the workload on employees.”

— Technical Director

Implementation

The initial phase of the transformation focused on establishing structured processes for core activities while reinforcing the “customer vs supplier” relationship model.

Key elements were mapped, including:

- Information flows

- Control mechanisms

- Systemic sources of data

- Capacity for generating and managing information

Internal goals, shareholder expectations, and regulatory commitments were reviewed to align transformation objectives with strategic and compliance requirements.

Critical control points were defined, along with:

Daily measurement frequencies

Clear operational and performance indicators

Workstations were redesigned with automation prerequisites in mind, enabling:

- Identification of tasks suitable for automation

- Standardisation of processes across functions

- Standardisation efforts began with material descriptions and coding for the client’s concession, laying the groundwork for scalable automation.

As part of the first wave of automation:

- Activities were mapped and standardized

- Measurement frequencies were formalized

- Automation prerequisites were finalised

- Initial automation was implemented at the early stages of the project lifecycle, with a particular focus on standardising materials listed in project documentation.

Result

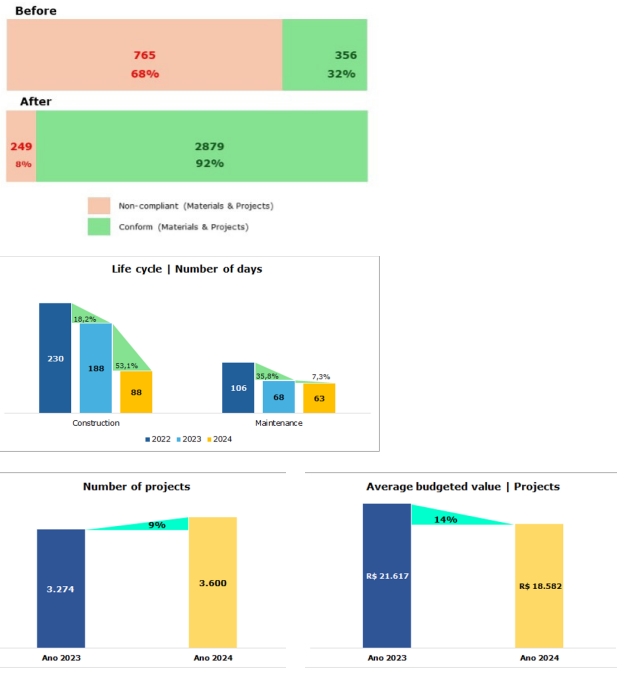

The chart above reflect a strong performance trend across key operational indicators, validating the effectiveness of process automation and standardisation initiatives.

Key Observations:

Manual Workload Reduction (12–16%)

The bar chart shows a clear downward trend in hours spent on manual tasks, confirming that the automation of routine administrative activities successfully freed up employee capacity for higher-value work.

Material Write-Off Reduction (9–13%)

The charts demonstrate a steady decline in material waste or discrepancies, directly tied to the standardization of material descriptions and codes. This outcome not only improved cost efficiency but also increased supply chain accuracy.

Improvement in Regulated Step Compliance (19–26%)

A marked increase in the successful execution of regulated processes reflects the benefits of clearer control points, better documentation, and daily monitoring of indicators. This suggests enhanced regulatory readiness and reduced risk of non-compliance.

Budgeting Compliance Surge (180%+)

The most significant charted result is the spike in budgeting compliance. The standardisation of project inputs and automated validation checks appears to have had a dramatic impact on planning accuracy, driving consistency between planned and actual project budgets.

Additionally, the client now benefits from:

- Greater transparency and control across project stages

- Automated, real-time tracking of critical operational metrics

- Standardized data that enhances decision-making and resource allocation

- Implemented daily control of project steps and system-based activities

- Ensured 100% material verification and standardization in project reserves

Renoir’s structured approach—focusing on automation, standardization, and performance tracking—delivered tangible and sustainable improvements. These results not only enhanced operational efficiency but also contributed to better regulatory performance, cost control, and decision-making accuracy.

*We have intentionally omitted client-specific details to maintain strict confidentiality.

Transform complex operational functions through automation and process standardisation