At a Glance

The client was looking to improve its organisational structure, process efficiency, and organisational behaviour through new ways of working. With an updated Management Control System installed by Renoir, they achieved savings of $10.3 million.

Key results

$10.3 mil

Reduction in annualised labour costs

100%

Achievement of proposed financial results and cost reduction

4.8:1

Return on investment

About the client

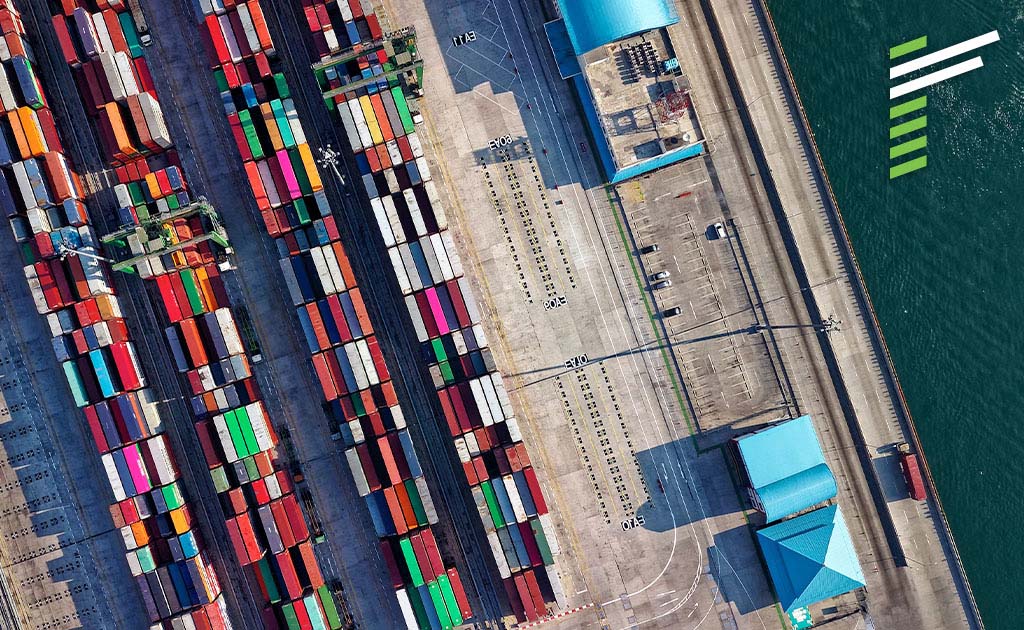

Our client is a company that manages the movement of cargo from ports in various parts of the world.

The challenge

The company was facing increasing pressure from various stakeholders. Shareholders, for one, were pressing for results, cost reduction, better communication and transparency. Competition was also expected to increase due to overcapacity. The organisation needed to be more efficient and productive to support these changes.

However, the organisation lacked readiness for sustainable growth.

Ineffective organisational structure

The company’s organisational structure and support processes were not designed for rapid response to volume variations. Further, unclear strategic alignment across the organisation and the lack of clarity in reporting lines hampered the company’s growth as management had difficulties driving strategic plans to lower levels.

The company also had a top-heavy managerial structure.

Lack of Management Control Systems and standard processes

The company’s systems had grown organically over the years but were poorly aligned with the company’s strategic targets. Although much data and information existed, few KPIs measured productivity and performance. The company lacked visibility on compliance and execution performance levels and had difficulty in identifying variances and root causes of problems, which caused unwanted events to recur.

Organisational behaviour that did not support growth

Employees were often firefighting problems of the moment. Due to unclear roles and responsibilities and a lack of accountability, there were misoriented efforts and low levels of sustainability of implemented actions and initiatives.

MCS Boosts Equipment Availability and Productivity for Port

Clear KPIs and Communication Accelerate Construction Project

MCS Boosts Equipment Availability and Productivity for Port

Clear KPIs and Communication Accelerate Construction Project

Ready for a change in your organisation?

What we did

To create a more effective organisation, we had to address more than the structure alone. Together with a task force from the company, we redesigned the company’s organisation structure, systems and processes to work together to stimulate “wanted behaviour” and ever-increasing performance.

- Designed a new organisation structure: The structure was redesigned to improve alignment to work processes and new tools were created to control or scale future labour requirements.

- Optimised processes: Processes were reviewed and documented with standard operating procedures. We designed and implemented process management control systems in all areas together with the task force, as well as improved formal communication, management performance reviews and action plans for increased functional performance.

- Adjusted organisational behaviour: Job descriptions were rewritten in accordance with new structure functions, roles and responsibilities. After the new organisational design was implemented, all affected personnel were trained in the new ways of working.

Renoir also trained “internal consultants” within the company to identify and work on future areas of opportunity geared towards prevention rather than cure.

Results

In addition to the $10.3mil labour cost reduction, the transformation programme delivered:

- A structure for the operations, administration and support functions

- Key processes and interfaces aligned with operating procedures

- Improved communication levels within the organisation

- Trained managers

- An internal group of qualified professionals to leverage the knowledge acquired

The company is now a more efficient, future-ready company, working within standardised processes and management control systems.

* We take client confidentiality seriously. While we have kept the brand anonymous, the results are real.

Optimise business processes for significant cost savings.