At a Glance

- The client, an oil and gas giant in Europe, was struggling with an escalating maintenance backlog, low technician productivity, and inconsistent work management practices.

- With Renoir’s support, the client reduced overdue maintenance orders by 30%, improved supervisory time in the field, and increased execution efficiency.

- This case study explores how Renoir helped the client transform its work management system and enhance operational excellence.

Key results

35% increase in hours executed in the field

Reduction of over 2,100 maintenance orders, representing a 30% backlog decrease

Maintenance order overdue percentage dropped from 37% to 19%

Supervisory time in the field increased from 33% to 43%

Improved alignment, processes, and communication across all stakeholders

Background

The client is one of the world’s leading oil and gas companies with vertically integrated operations across upstream, refining, distribution, marketing, and trading. The refinery at the centre of this project has a capacity of 400,000 barrels per day and plays a key role in supplying global energy markets. Despite its scale and expertise, the organisation faced challenges in effectively managing refinery work, particularly in ensuring operational consistency across its workforce of thousands of employees.

Analysis

The client turned to Renoir due to growing concerns over an escalating annual maintenance backlog, particularly overdue orders that risked compromising operational control. The situation was further complicated by inadequate utilisation of Refining Work Management (WM) best practices, which posed a significant barrier to the company’s planned transition to SAP S/4HANA. Renoir was brought in as a trusted partner to stabilise performance and establish a sustainable framework for improvement.

A comprehensive assessment of work management practices was carried out through shop floor observations, interviews, workshops, and data analysis. This revealed several underlying challenges:

- Technician wrench time was significantly below standard at just 29%, caused largely by weak scheduling processes and poor-quality work preparation.

- Although local procedures closely reflected global Refining WM standards, adherence was inconsistent due to insufficient training and a lack of clarity in application.

- Broader organisational issues around culture, behaviours, and performance management were evident. Existing meetings lacked clear KPIs, reducing effectiveness, alignment, and oversight.

Project Approach

Renoir’s strategy was built around two core objectives:

- Enhance executional productivity to reduce the backlog and mitigate risks.

- Ensure consistent adherence to standardised Refining Work Management practices.

The project began with a Focus Phase®, during which Renoir conducted a detailed root cause analysis, engaged frontline teams, and defined improvement actions. Local teams were trained and coached in the new operational approach, supported through change management to facilitate adoption of the new standards.

A scrum sprint methodology was deployed to drive progress, with each MAT holding two working sessions per week. To ensure visibility and accountability, MAT leads presented content and progress reports in fortnightly sponsor meetings, which in turn informed governance meetings with the site leadership team and the global client group. This structure ensured continuous alignment, rapid problem-solving, and measurable results throughout the project.

Ready for a change in your organisation?

“Due to the MCS leading and lagging indicators, we are now able to monitor the work management processes, and now can steer upon data. Renoir was able to provide us with a professional and multiple disciplined team, bringing a good mix between theoretical and practical experience.”

– Maintenance and Engineering Manager

Implementation

To drive lasting change, Renoir and the client shifted from traditional top-down information sessions to bottom-up performance meetings that encouraged action-oriented discussions and strengthened the PDCA (Plan-Do-Check-Act) cycle. This approach empowered frontline leaders and created a culture of accountability.

First and second-line shop floor leaders were trained and coached to improve preparation quality. The time saved from better planning and scheduling was reinvested into work execution, directly boosting productivity.

Renoir’s collaborative model placed the client in the lead, with Renoir providing expertise in communications, stakeholder engagement, and change management. This ensured that improvements were both technically sound and culturally embedded.

Key activities implemented during the project included:

| Area of Focus | Actions Taken |

| Work Notifications | Trained every notification creator in best practice standards |

| Risk Management | Introduced objective risk ranking validation aligned with global standards |

| Planning & Scheduling | Enhanced planning processes, procedures, and work instructions; created a planning handbook; provided standardised training for new and existing employees |

| System Optimisation | Adjusted SAP parameters to improve material availability and uploaded accurate supplier lead times |

| Scheduling Discipline | Established stage gates with strict readiness criteria; corrected planning errors before schedule lock; proactively resolved non-readiness issues |

| Execution & Feedback | Mapped roles and responsibilities for effective task completion; introduced a feedback loop for continuous improvement |

| Meetings & Performance | Replaced ineffective sessions with structured focus meetings; updated Terms of Reference; introduced KPIs and dashboards to track performance; raised meeting maturity levels |

Results

The project delivered measurable improvements across productivity, backlog management, supervisory effectiveness, and overall work management practices. Updated procedures, enhanced training, and the introduction of performance-driven KPIs created alignment and accountability at all levels of the organisation.

The accompanying charts further demonstrate the transformation:

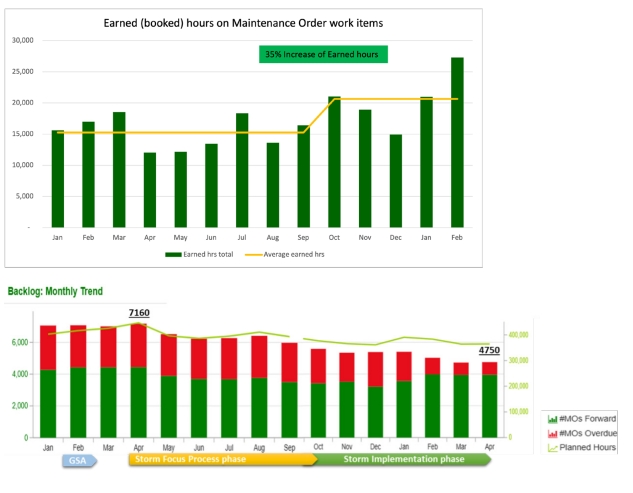

Earned Hours on Maintenance Orders: The top chart shows a 35% increase in earned (booked) hours on maintenance order work items, indicating a step-change improvement in technician productivity.

Backlog Monthly Trend: The lower chart highlights the backlog reduction, with maintenance orders decreasing from a peak of 7,160 to 4,750 by the end of the project. The visual also shows the transition across the Focus and Implementation phases, reinforcing the effectiveness of Renoir’s structured approach.

Through the course of project after implementation phase, the refinery achieved significant operational gains:

| Performance Area | Before Renoir | After Renoir | Impact |

| Technician Productivity (Hours Executed in the Field) | Baseline | +35% | Substantial increase in field execution efficiency |

| Maintenance Backlog | High backlog with >7,000 orders | Reduced by >2,100 orders (30% reduction) | Improved operational stability and reduced risk |

| Overdue Maintenance Orders | 37% overdue | 19% overdue | Backlog brought under control |

| Supervisory Time in the Field | 33% | 43% | Stronger coaching and oversight of frontline teams |

| Meeting Effectiveness | Top-down, limited KPI usage | Action-oriented meetings with clear KPIs and dashboards | Improved alignment, ownership, and decision-making |

*Client-specific details have been intentionally omitted to maintain strict discretion.

Reduce backlogs and boost productivity .