Background

Contracting and construction companies play a crucial role in various aspects of society and the economy. These companies are responsible for building and developing essential infrastructure such as roads, bridges, airports, and utilities, which are necessary for economic development and job creation.

They carry out activities within the construction industry such as project execution, resource management, subcontracting, and providing expertise and services in engineering, project management, architecture, and construction techniques, to name a few.

Labour productivity is essential for contracting and construction companies as it impacts project timelines and delivery, cost efficiency, operational efficiency, and profitability. By focusing on enhancing labour productivity, companies can achieve better financial performance and client satisfaction, and therefore, remain competitive in this highly competitive industry.

Our client is a major contracting and construction company in the Middle East with Engineering, Procurement, and Construction (EPC) capabilities in several sectors including Oil & Gas, as well as Utilities. Established in the 1970s, our client has grown into one of the largest construction companies in the Middle East with revenues over US$1 billion.

Project Approach

Our client commissioned Renoir to improve direct and indirect workforce productivity at its Sewerage Treatment Plant (STP) project as soon as possible. Renoir designed a 12-week Rapid Intervention Programme (RIP), split into two phases:

- One-week of in-depth productivity analysis and a site assessment to understand the challenges and develop solutions to boost employees’ productivity, and;

- 11-week implementation stage to apply the solutions

Project Implementation

Our client also assigned several of its full-time employees to the Project Task Force (PTF) that enabled better buy-in, overcame the challenges encountered, and for post-project sustainable, continuous improvement.

The project was governed by a steering committee consisting of the company’s executive team. All issues and concerns were reviewed by this steering committee to ensure the project’s success.

Project Deliverables

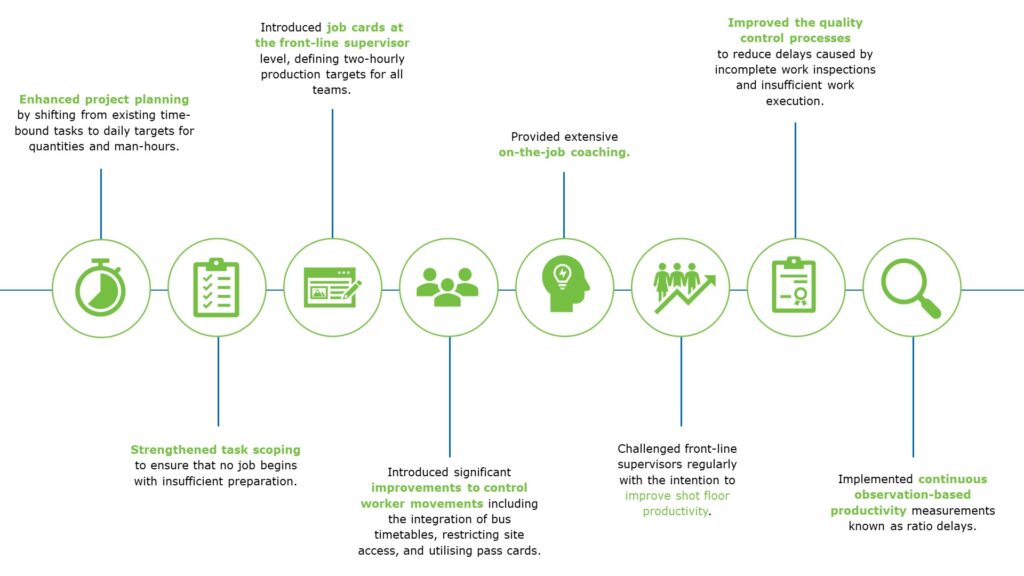

At the beginning of our project, we found that nearly 20% of the workforce was excluded from the planning process. Here are some of the tasks undertaken to boost labour productivity:

- Enhanced project planning by shifting from existing time-bound tasks to daily targets for quantities and man-hours.

- Strengthened task scoping to ensure that no job begins with insufficient preparation.

- Introduced job cards at the front-line supervisor level, defining two-hourly production targets for all teams.

- Introduced significant improvements to control worker movements including the integration of bus timetables, restricting site access, and utilising pass cards.

- Provided extensive on-the-job coaching.

- Challenged front-line supervisors regularly with the intention to improve shot floor productivity.

- Improved the quality control processes to reduce delays caused by incomplete work inspections and insufficient work execution.

- Implemented continuous observation-based productivity measurements known as ratio delays.

Apart from enhancing productivity, there was also a pressing need to improve production across all work areas. We focused on major commodities involved in the project, such as backfilling, scaffolding, blockwork, plastering, and painting, as well as addressing challenges along the supply chain. We implemented the following changes:

- Established primary metrics for measuring commodity production.

- Implemented monitoring mechanisms for tracking progress in ancillary areas of concern, such as technical delays and materials supply.

- Daily evaluations of supervisory performance and weekly comprehensive reviews at the site level

- Provided coaching to middle management on improving root cause analysis and communication effectiveness.

Results

“The STP project has in the space of 3 months been transformed from one of the worst productivity sites in the company to the best.”

– CEO

An increase of over

60%

in direct labour productivity

Key production commodity up by

400%

One of the initial focal points was the utilisation of the workforce, which was measured by dividing the planned hours by the available (salaried) hours. At the end of our RIP, there were improvements in the weekly and daily planning to quantities and man hours. The manpower utilisation rate was 97% on week 12.

The Operational Excellence Advantage

Improving labour productivity is a crucial component of achieving operational excellence. Operational excellence is not a destination that can be reached with a single effort; it is a continuous journey of improvement.

This case study, which is based on an actual project, aims to provide insights and demonstrate Renoir’s expertise in the subject matter. However, we have intentionally omitted client-specific details to uphold strict confidentiality.