At a Glance

- Asian oil and gas major lacked visibility into fuel consumption across 150+ vessel fleet, leading to excess allocation and inefficient operations.

- Implemented structured change management approach with new fuel monitoring tools and processes to target high-consuming vessels.

- Achieved 25% fuel reduction and USD 36.7 million annualized savings with 50x ROI while significantly lowering carbon footprint.

Key results

50X ROI versus project cost

25% fuel consumption reduction

USD36.7 million annualised savings

146,000 tons of carbon emission reduced

Background

Asia’s offshore energy sector is underpinned by a rapidly growing fleet of over 500 contracted Offshore Support Vessels (OSVs), with demand expected to exceed 600 vessel years by 2026. These vessels are largely tied to long-term contracts, pushing utilisation rates higher and limiting fleet flexibility. Fuel consumption across these assets is significant—support vessels typically burn around 50 barrels per day, construction vessels up to 300 bpd, and rigs around 200 bpd—making fuel one of the largest cost drivers in offshore logistics.

The client, a major Southeast Asian oil and gas operator, manages over 150 OSVs across three regions. With fuel costs comprising nearly half of its logistics division’s budget, the company faced mounting pressure to improve efficiency and sustainability, prompting a strategic overhaul of its fuel management practices.

Analysis

Although the company had robust systems and reporting procedures in place, gaps in real-time tracking and standardisation were hindering fuel management. The fuel allocation per vessel varied widely, and monitoring protocols were often discretionary.

Key issues identified included:

- Lack of live fuel consumption tracking per vessel.

- Inconsistent fuel allocation standards.

- Absence of rigorous leak detection and consumption benchmarks.

- Monthly recoupment processes that were too slow to respond to anomalies.

- Unclear accountability for fuel use at various operational levels.

With decarbonisation targets looming and escalating operational costs, it became imperative to drive a systemic transformation of their fuel management processes.

Ready for a change in your organisation?

Project Approach

Renoir Consulting designed a targeted, five-pronged strategy to address these systemic challenges:

XXX insert table xxxxxxxx

Implementation

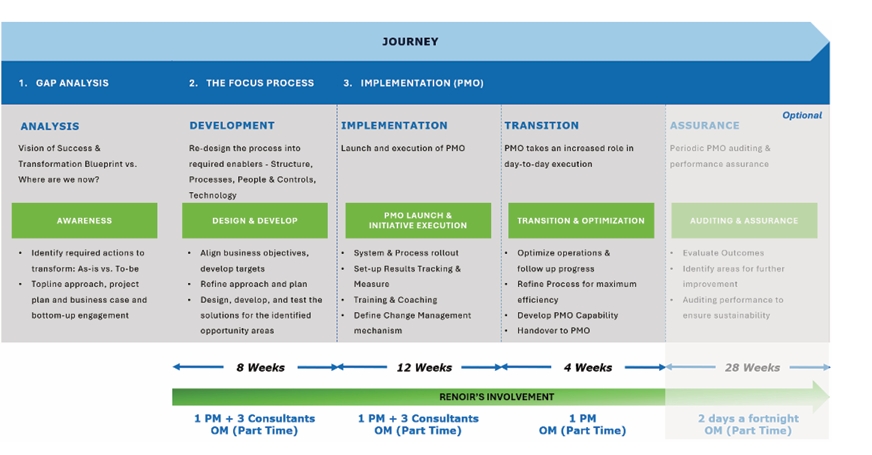

The visual illustrates Renoir Consulting’s structured multiweek transformation journey, broken into five stages: Gap Analysis, The Focus Process, Implementation (PMO), Transition, and optional Assurance.

Each phase is designed to drive sustainable operational change, supported by a blend of consultants and part-time client-side operational managers.

Key initiatives included:

- Setting up a centralized dashboard for cross-regional fuel tracking.

- Instituting weekly and monthly fuel performance meetings across all layers of management.

- Deploying escalation protocols and a new communication strategy to address outliers in vessel consumption.

- Introducing simple, spreadsheet-based analysis tools for field supervisors to dissect usage metrics effectively.

- Coaching and capability building to empower internal teams to own and sustain changes post-project.

Results

The collaboration led to a swift and significant transformation:

- Within six months, the client surpassed their annual savings stretch goal, recording (USD36.7 million) in annualised savings.

- Vessel fuel consumption dropped by 25% compared to the previous year.

- Carbon emissions were cut by 146,000 tons—an impactful stride towards environmental sustainability.

- The project generated a 50X return on investment, demonstrating the cost-effectiveness and strategic value of Renoir’s approach.

- Most importantly, the client was equipped with systems and skills to continue driving improvements independently, ensuring the sustainability of the results beyond the project timeline.

*We have intentionally omitted client-specific details to maintain strict confidentiality.

Transform offshore logistics with fuel efficiency experts