Large organisations, especially those managing thousands of warehouses and vast material inventories, often face significant procurement challenges:

- High consumption of materials with low visibility into stock movement and demand.

- Inefficient procurement processes driven by urgency rather than strategy.

- Stock inaccuracies, losses, and obsolescence.

- Poor categorisation and lack of procurement strategies aligned to business priorities.

In many cases, procurement teams operate reactively, responding to material requests rather than proactively planning and leveraging economies of scale.

Key Challenges in Procurement and Inventory Management

Transactional Procurement

- Procurement is driven by immediate requests rather than demand forecasting.

- Limited volume leveraging due to fragmented purchases.

- Suppliers may apply penalties or offer higher prices when contracts lapse.

Stock Inaccuracies and Material Loss

- System stock levels often differ from physical inventory, leading to over-purchasing.

- Issues include theft, unrecorded consumption, or damaged stock.

- Poor visibility across warehouses results in redundant purchasing.

Inefficient Vendor and Contract Management

- Over-reliance on a large number of low- to medium-value vendors.

- Poor compliance with preferred supplier agreements.

- Expired contracts and lack of governance over procurement processes.

Lack of Procurement Strategy

- Spend is not categorised based on risk, value, or importance.

- Critical items are not identified for strategic sourcing.

- No defined approach for high-value or low-value purchases.

A Strategic Procurement Transformation Framework

Leverage Procurement Data to Drive Strategic Decision-Making

Mastering data management forms the foundation of procurement transformation. Clean, accurate data enables better decision-making, demand forecasting, and cost control.

Key Initiatives:

- Standardise and clean existing procurement and inventory data.

- Implement robust inventory classification (e.g., fast-moving vs. slow-moving, critical vs. non-critical).

- Centralise visibility across all warehouses for stock levels and consumption trends.

Category-Based Procurement Strategies

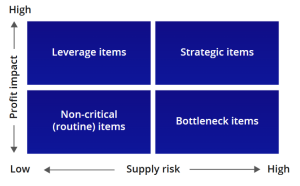

Applying strategic procurement principles, such as the Kraljic Matrix, enables organisations to differentiate between spend categories and implement targeted procurement strategies.

| Category | Strategy | Example |

| Strategic Items | Develop long-term partnerships with suppliers | Critical materials for operations |

| Leverage Items | Volume consolidation for better pricing | Standardised cables or spares |

| Bottleneck Items | Diversify suppliers to mitigate risks | Specialised equipment parts |

| Non-Critical Items | Local purchasing with minimal oversight | General consumables |

The above table is an example of an organization’s targeted procurement strategies according to the Kraljic Matrix as illustrated in the diagram below.

Optimised Inventory Management

Efficient inventory management reduces stock inaccuracies, minimises losses, and optimises warehouse operations.

Key Initiatives:

- Demand Forecasting: Implement predictive tools to align procurement with material consumption trends.

- Inventory Accuracy Audits: Regular cycle counts to identify and address discrepancies.

- Warehouse Visibility: Utilise technology to enable centralised tracking and cross-warehouse transfers.

- Stock Optimisation: Maintain minimum/maximum stock levels to prevent overstocking and stockouts.

Process Governance and Compliance

Improved procurement and inventory outcomes depend on clearly defined roles, responsibilities, and processes.

Key Initiatives:

- Strengthen compliance to procurement policies and supplier contracts.

- Define clear approval workflows for purchase requisitions and contract renewals.

- Enhance accountability by monitoring procurement performance KPIs.

In our next article in the series, we discuss the three phases of building an implementation roadmap for strategic procurement transformation, and the numerous benefits data-driven procurement can bring organisations. Read our next article, “Building an Implementation Roadmap to Achieve Data-Driven Procurement”.

About the Author

Paul Archer has over 30 years of experience in driving operational excellence and implementing transformative business strategies. With a career spanning multiple industries, Paul has worked extensively in procurement, inventory management, and organisational optimisation. His hands-on approach and deep expertise enable businesses to unlock efficiency and achieve measurable outcomes. Paul is currently associated with Renoir Consulting, where he continues to deliver high-impact solutions to complex operational challenges.

Connect with us

Let us work with you to achieve exceptional results.