At a Glance

- A major player in the petrochemical industry, faced critical challenges in maintenance productivity and operational efficiency.

- Key issues included high corrective maintenance rates, poor supervision, and inconsistent planning and scheduling.

- By partnering with Renoir, the client achieved a significant increase in plant availability from 89% to 92%.

This case study explores the transformation journey towards standardised and sustainable maintenance operations.

Key results

- Plant availability improved to 92% from a baseline of 89% (PTA Plant)

- Overall Equipment Effectiveness (OEE) increased to 92% from 87% (PTA Plant)

- Preventive Maintenance Plan compliance rose from 46% to 74%

- Full organisational redesign of the maintenance department implemented

- Introduction of a new process flow to qualify anomalies at the source

- Systematic optimisation of preventive maintenance routines

- 1,300 man-hours of training on management capabilities and interdisciplinary integration

Background

The client is a major petrochemical manufacturer with operations across North and Latin America. It operates in two core segments: polyester production—including PTA, PET, and polyester fibres—and chemicals such as polypropylene, expandable polystyrene, and caprolactam. They hold a leading market position in multiple products lines and operate several large-scale plants that supply industrial clients across the hemisphere.

Analysis

The project was initiated due to several persistent operational issues:

- A high proportion of corrective maintenance work orders (45%)

- Poor adherence to the existing Maintenance Management System

- Lack of preventive coverage for critical equipment

- Low compliance with planning and scheduling practices

- Inefficient supervision and insufficient time spent in the field.

These challenges resulted in productivity losses and limited the client’s ability to maintain reliable and continuous operations.

Project Approach

The client initially launched a multiweek Maintenance Excellence Project focused on enhancing productivity and operational reliability through process improvements, updated procedures, and the implementation of a new management system across maintenance operations. Solutions were developed and implemented consistently across both the PTAC and PET plants, with only minor adaptations to accommodate plant-specific conditions. The initiative focused on improving productivity and operational reliability by redesigning processes and implementing a new management system.

It began with Focus Process® to validate opportunities, followed by implementation and a sustainability phase. The programme aimed to reduce non-value-adding activities, embed a culture of continuous improvement, and enhance OEE and operational continuity.

This programme was structured around two Management Action Teams (MATs):

- OEE Management & Reliability Improvement, which focused on embedding a culture of continuous improvement

- Maintenance Management, which targeted reducing deviations and optimising execution time.

Both MATs were multidisciplinary, ensuring broad engagement from technicians, safety and production personnel. This inclusive structure was essential in laying the foundation for long-term operational improvements.

“Due to the implemented maintenance management system, we are more integrated and therefore we have reached operational continuity. Most importantly we work even more under safe conditions.”

—Operations Manager

Rotating Equipment Management Improves in LNG Plant

Reduce Operating Costs with Optimized Performance Management

Management system drives efficiency and contractor compliance

Ready for a change in your organisation?

Implementation

The programme began with Renoir’s Focus Process®, where existing systems were analysed and improvement opportunities validated. In collaboration with the client, new indicators and performance routines were designed. Key initiatives included:

- Development of an integrated full Maintenance Management Control System and its Management Tools .

- Implementation of tools such as the Frozen Weekly Schedule (activities and resources), Short Interval Control tool and routine (deviation and action taken), Maintenance Performance Reports and Performance Review Meeting Routines.

- Establishment of active supervision routines and contractor management systems

- Engineering-led optimisation of preventive maintenance routines

Improvements to processes and systems enabled the client to plan and manage daily maintenance activities more effectively, resulting in fewer unplanned interruptions, reduced backlog, and enhanced productivity. The more effective application of maintenance methodologies such as failure mode analysis for critical equipment contributed to the increase in OEE.

“The project has brought us a management system that made us to work under planned priorities seeking better efficiency performance, and, consequently, Productivity.”

—Maintenance Manager

Results

Summary of Report:

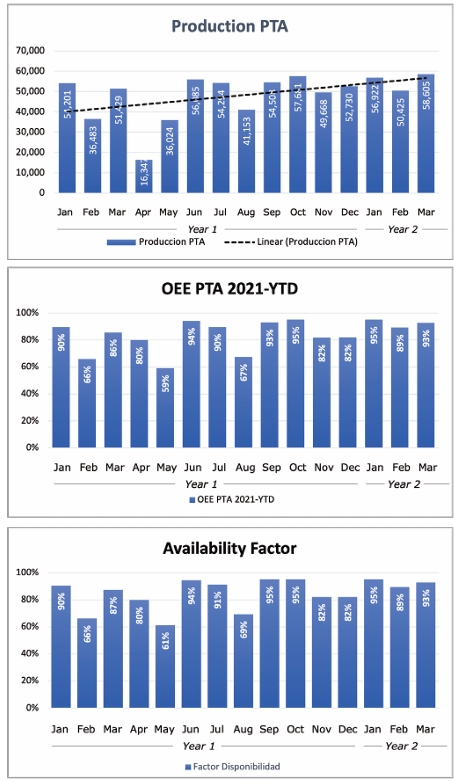

- Production increased from ~35,000 to over 58,000 tonnes within 14 months

- OEE improved from 59% to consistently above 90%

- Availability Factor rose from 66% to 95%

- Sustained improvements reflect enhanced reliability, planning, and execution control across the PTA plant

| Performance Area | Before Renoir Intervention | After Implementation | Impact |

| Production Volume (PTA) | ~35,000 tonnes (Feb, Year 1) | >58,000 tonnes (Mar, Year 2) | Steady increase in monthly output driven by improved maintenance planning |

| OEE (Overall Equipment Effectiveness) | Fluctuated between 59% and 80% | Consistently above 90% in final months | Reflects enhanced execution control and preventive maintenance |

| Availability Factor | Ranged from 66% to 84% | Stabilised above 90%, reaching 95% in peak months | Demonstrates higher asset reliability and reduced unplanned downtime |

Struggling with unplanned downtime and inefficient maintenance processes?